Silicon steel mother coils, also known as electrical steel or transformer steel, are specialized metal products crucial to the electrical and electronics industries. These coils are made from high-grade silicon-alloyed steel, typically containing 2-3.5% silicon content. The addition of silicon enhances the material's magnetic properties, particularly its magnetic permeability and low core loss characteristics. Mother coils are large, primary rolls of silicon steel that serve as the starting point for various downstream products. These coils are produced through a carefully controlled manufacturing process involving melting, casting, hot rolling, and cold rolling. The resulting material features a grain-oriented structure that optimizes magnetic flux alignment in one direction. Silicon steel mother coils are typically available in thicknesses ranging from 0.23mm to 0.35mm and widths up to 1000mm. They are characterized by their good magnetic properties, including high magnetic saturation, low hysteresis loss, and minimal eddy current loss. These attributes make them ideal for applications in transformers, electric motors, generators, and other electromagnetic devices.

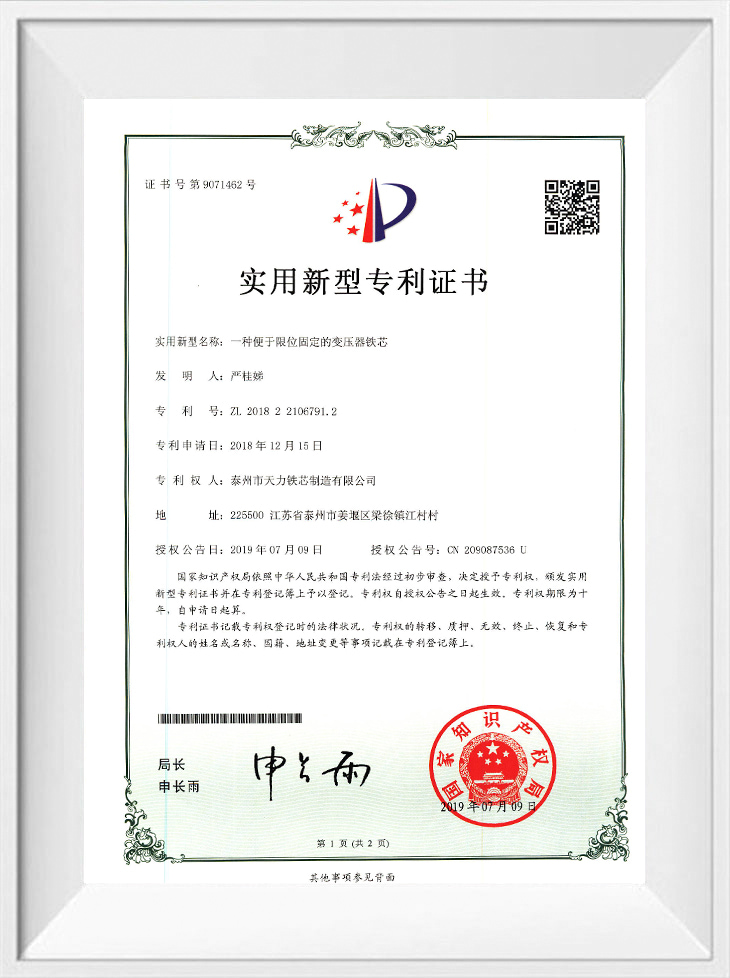

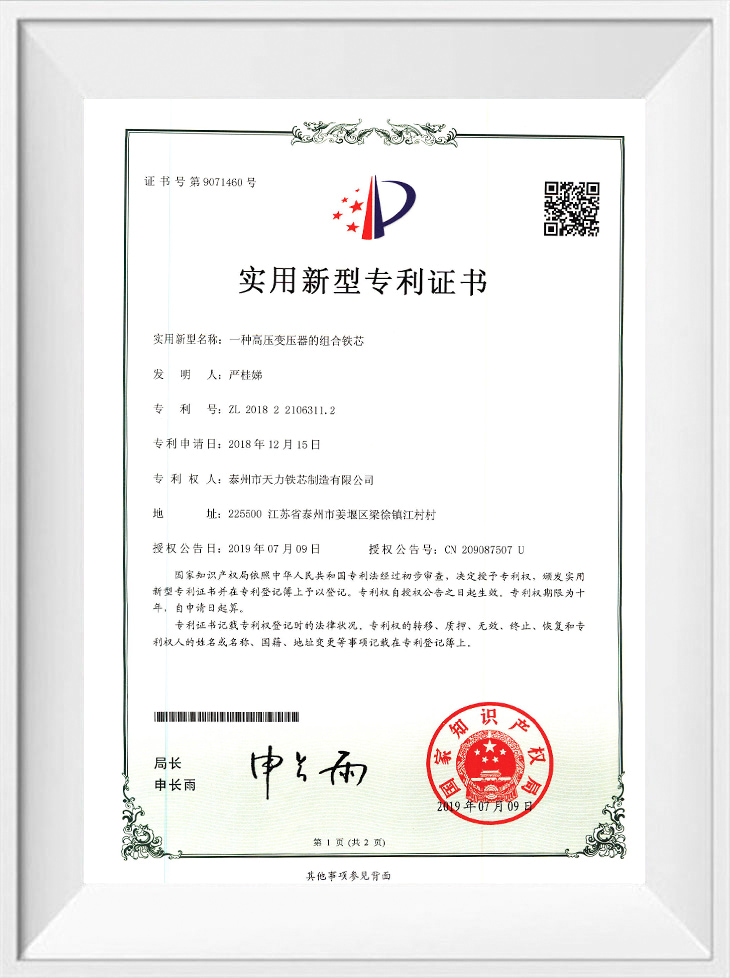

Taizhou Tianli Iron Core Manufacturing Co., Ltd. is China Silicon Steel Mother Coils manufacturers and OEM/ODM Silicon Steel Mother Coils company. Established in 2009, Tianli Iron Core is a leading full-solution provider of transformer core materials and assemblies. We specialize in slitted coils, core laminations, and precision-assembled magnetic cores for distribution and power transformers. With a strong technical foundation and materials sourced from top-tier mills like Shougang and Baosteel, we deliver reliable, high-performance solutions tailored to each client’s needs. Our experienced team ensures quality, flexibility, and responsive service across global markets. From material selection to final core assembly, Tianli is committed to powering your success—efficiently and dependably.

Your trusted partner in transformer core excellence.

Silicon steel mother coils, often referred to as electrical steel or transformer steel, are critical materials in the electrical and energy industries...

View MoreDry-type transformers are widely used in commercial and industrial settings due to their unique advantages in terms of safety, reliability, and enviro...

View MoreSilicon steel slitting coils play a critical role in the manufacturing of electrical transformers, motors, and other electromagnetic devices. They are...

View MoreTransformer cores are at the heart of modern power distribution systems. Their function is to provide a magnetic path that efficiently transfers energ...

View MoreDry-type transformers are essential components in electrical distribution systems, particularly in commercial, industrial, and residential environment...

View MoreHow do silicon steel mother coils perform in renewable energy systems compared to traditional applications?

Silicon steel mother coils play a crucial role in both traditional electrical applications (e.g., transformers, motors, and generators) and renewable energy systems (e.g., wind turbines, solar inverters, and EV motors). Here's how their performance compares in these two contexts:

Efficiency and Core Losses

Traditional Applications: In transformers and motors, silicon steel is primarily used to reduce core losses (hysteresis and eddy current losses) and improve energy efficiency. The grain-oriented (GO) version is especially used in transformers for aligning magnetic flux to reduce losses, while non-grain-oriented (NGO) steel is preferred for electric motors.

Renewable Energy: In renewable energy systems, efficiency is even more critical due to intermittent energy sources like wind and solar. Silicon steel coils used in wind turbine generators and solar inverters need to minimize core losses to maximize power conversion efficiency. Higher-grade silicon steels with lower core loss values are increasingly preferred in renewable applications to meet stricter energy efficiency requirements.

Performance in High-Frequency Applications

Traditional Applications: In typical transformer and motor applications, the operational frequencies are generally lower (50/60 Hz). Silicon steel performs well at these frequencies by reducing magnetic losses and maintaining energy efficiency.

Renewable Energy: Renewable systems, especially inverters used in solar power and wind turbines, often operate at higher frequencies. Silicon steel coils in these systems must exhibit low core loss at high frequencies to ensure efficiency and reliability. Non-grain-oriented silicon steel is typically used for these high-frequency applications, as it can better handle fluctuating frequencies without significant losses.

Thermal Stability and Durability

Traditional Applications: Silicon steel’s thermal stability ensures reliable performance in high-power transformers and electric motors, where heat dissipation is a concern, but operating conditions are often more controlled.

Renewable Energy: In renewable energy systems, such as wind turbines, electric vehicle motors, and solar inverters, operating environments can be more extreme with temperature fluctuations and varying loads. Silicon steel mother coils used in these applications must withstand these stresses while maintaining magnetic properties and minimizing degradation over time. Newer silicon steel grades with higher thermal stability are essential for these systems.

Material Requirements for Compact Designs

Traditional Applications: Silicon steel has been traditionally used to reduce the size of transformers and motors while maintaining efficiency, but space limitations are usually not as stringent as in some renewable systems.

Renewable Energy: In applications like electric vehicles and wind turbines, space and weight constraints are critical. As a result, high-performance silicon steel mother coils with thinner profiles (0.23mm and below) are often preferred to reduce the size and weight of components without sacrificing efficiency. This requirement is especially relevant in electric vehicle motors, where space-saving, high-efficiency materials are crucial.

Magnetic Saturation and Flux Management

Traditional Applications: Silicon steel’s ability to handle high magnetic flux densities makes it ideal for traditional applications, ensuring that transformers and motors can operate effectively under various loads.

Renewable Energy: In wind turbine generators and electric vehicle motors, the demand for high magnetic saturation is even more critical. Renewable energy systems often require materials that can handle strong magnetic fields while maintaining low energy losses. Silicon steel with higher magnetic saturation improves the energy yield of wind turbines and other renewable technologies.

Magnetic Saturation and Flux Management

Traditional Applications: Silicon steel’s ability to handle high magnetic flux densities makes it ideal for traditional applications, ensuring that transformers and motors can operate effectively under various loads.

Renewable Energy: In wind turbine generators and electric vehicle motors, the demand for high magnetic saturation is even more critical. Renewable energy systems often require materials that can handle strong magnetic fields while maintaining low energy losses. Silicon steel with higher magnetic saturation improves the energy yield of wind turbines and other renewable technologies.

Sustainability and Green Technology

Traditional Applications: While efficiency has always been important in traditional systems, the push for sustainability has been less urgent compared to the renewable energy sector.

Renewable Energy: With the global emphasis on sustainability, renewable energy systems prioritize environmentally friendly, energy-efficient materials. Silicon steel mother coils, particularly in smart grid components and energy-efficient motors, contribute to lowering the carbon footprint of renewable systems. High-efficiency silicon steel reduces the overall energy loss, making these systems more sustainable and aligned with green technology initiatives.

Summary of Performance in Renewable Energy vs. Traditional Applications:

Higher Efficiency: Renewable systems demand even higher efficiency, driving the need for low-loss, high-grade silicon steel.

High-Frequency Adaptability: Silicon steel used in renewable applications must perform well under higher and fluctuating frequencies, a more demanding requirement than in traditional systems.

Thermal and Environmental Durability: Renewable applications, especially in electric vehicles and wind turbines, require materials with greater thermal and environmental durability.

Compact and Lightweight Design: Renewable energy systems often require compact, lightweight materials, where thin, high-performance silicon steel plays a key role.

Silicon steel mother coils are indispensable in both traditional and renewable energy systems, but the demands of renewable technologies require higher grades of silicon steel for superior performance in terms of efficiency, adaptability, and durability.